What Foil manufacturer do you recommend Mike King?

Ladies and Gentlemen, at every first-time meeting, this is one of the most asked questions. After 45 years of working with foil, I have learned that all foils work for the most part. When I say, for the most part, I say with years of experience in hot foil and cold foil. In the hot foil world, there are various formulas that work for various types of work. Basically, there is 2 kinds of work, fine line and details, and the other large solids. In the cold foil world, we have the same but for the most part with various tricks of the CF world, you can run anyone’s foil with large solid coverage or fine lines.

The biggest challenge to various foil manufacturers is the marriage between the components of the adhesive and the last layer of the foil, I call the sizing coat. Think about wallpaper in your home, the sizing coat is sometimes already on the paper. Or you put a layer of glue on the paper before hanging to the wall. Then you mate this to the glue, you put on wall and we are all happy and bonded well. The problem with the wallpaper that has the sizing coat layer on it from the store, they most times will not be the same chemistry and the bond will not be 100%. Wallpaper glue 99% of the times is so aggressive, it really does not matter.

We will now apply this same thought process in the cold foil world. Let us look at CF adhesives available in my marketplace. What do we look for here? To start, we really don’t know. Maybe UV, Conventional or LED, to start. There are plenty of UV & Conventional adhesives but not too many LED, but there are regular UV adhesives that are not LED rated but work fine in LED application. The problem is it doesn’t stop there. The chemistry also comes from your fountain solutions and some of the additive’s folks use today, in different parts of the country and/or the world, is quite different. Also, there are various curve balls like alcohol content in the fountain solution. Some presses actually allow you to adjust this level, while others use a replacement for alcohol because their country does not allow this chemical. Yes, alcohol is definitely your enemy with adhesive.

I have personally trained on site of the various foil manufacturers and their staff, so they are educated in this cold foil area, to get the best bond and performance with their foil to the various substrates. Eagle spends lots of money on the R&D of foil process. We have various techniques which allow us to find these windows of opportunity with all of the various brands of foils and adhesives combinations. This education has not made it to the press room, and the CF world has struggled a bit because of the transfer of this very important knowledge. Substrates play a lot with the best performance of CF process, and sometimes it’s not the high-quality board that does the best. Some applications on the most inexpensive boards give a better appearance than the high-end stocks. However, let’s get back to the basic, and the marriage between the sizing coat and adhesive brand you are using. What happens when the marriage fails between the adhesives and sizing coats? No bond to the substrate which means poor foil quality, rough edges, lead edge problems, or picking and lifting of the foil downstream in the printing press. If this happens then we have all types of problems and a simple process becomes a struggle. There are various tests that can be done on the press to confirm I have the right combination and I am going in the right direction.

Seeing the need to help to educate folks I have personally put lots of hours into my Eagle Cold Foil Certification. This brings folks to the levels they need to be, and the education needed to run CF, without a struggle. I always say, “Cold Foil is by the numbers and 100% mathematical. Hot foil is an art and like a doctor, you practice the art of hot foil all your life, but you never perfect.” There are many combinations of foil and adhesives today and not like 12 years ago, where we literally had one choice of foil and one choice of adhesive.

Most folks run one or two different adhesives at most. If you are running a specific brand foil, and you wish to try a totally different brand foil or even same brand different model or color, don’t believe your current adhesive is going to work the same as the one you have been using all along. However, it could work just fine, because your chemistry is spot on. This is also why some foil companies have rebranded adhesives and sell as packages. They have done their homework and they know the best combination. Something Eagle has been teaching for many years with all our partners.

Partners I refer to are the ones that own Eagle products in the last 29 years. Yes, Eagle will celebrate 30 years this coming January 1, 2020.

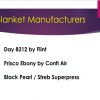

The world foil manufacturers are the following (PPC, Infinity, Dragon, ITW, Univacco, Kurz and API). In the adhesive field, there are in excess of 30 manufacturers worldwide and they offer adhesives in many forms such as UV, Conventional, LED, Low Migrations and Plastics formulas.

At Eagle we have a very small lab for making and testing various adhesives, and these adhesives are not for sale and only to experiment for various applications and substrates. We then share these formulas with our partners for the various applications.

The Risktaker stage of cold foil is over. There was a period of time various Foil companies led the world or regions in Cold foil and others were just not usable. During those times, there was a constant change of chemistry in the foil formulas and eventually, they slowly all dialed in the formulas.

My answer is all foils manufacturers today have gone through challenges and I can get anyone’s foil to work in anyone’s environment. Most foils are easy to run but the variables are different. On startups, Eagle brings a range of foils from all foil manufacturers and a variety of Eagle’s choice adhesives to assure a smooth startup. They are all making great products out there today and I have enjoyed the pleasure of working with them all for many years.