When looking for your next offset print environment upgrade there are a lot of factors to take into account. For example, will this new tool give you a competitive advantage? You also should assess the amount of downtime you might introduce into your print environment and whether the solution will work well in the long run with the current and future planned equipment on your print production floor. Being able to find something that can be tuned to your environment, offers a competitive advantage and opens the doors to more opportunity is in the same neighborhood as finding the perfect solution. And that is why you should turn to Eagle Systems.

Our Cold Foil solution will offer you the ability to produce foil embellishments without the hassle of putting your printed pieces through a secondary or offline foiling process. The Eagle Systems methodology is a simple two-step process that has been made as easy as touching a button. Moreover, our cold foil is installed inline allowing our clients to realize adding foil at the same speed their offset press runs at without the need to stop or slow down.

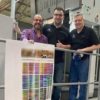

It is important at this point to note that an Eagle is not a one-size fits all solution. We make sure that we engineer each installation for your success; even when it is on a machine we haven’t installed on previously. Consider the experience one of our customers had when they installed our Eco-Eagle Cold Foil system on their very high-speed KBA Rapida 106 offset printing press. Rob Watts, Pressroom Manager at MacLean Packaging, had this to say about the Eagle Systems solution:

“With production speeds up to 18,000 sheets per hour, the KBA 106, the fastest press in its format class, we required an Eagle system that processes cold foil at corresponding speeds. With Eagle, every install is not only engineered for the press specs, but also the client’s specific requirements. It makes a major difference.”

It is that major difference that makes Eagle a partner, not just a vendor of print technology. We are in business to make our clients successful…and help make them money too. The benefits of the Eagle offering are tangible in our client environments. Watt continued in the original story on Printing Impressions to say this:

“Today, Eagle has enabled us to move well up the production cycle into the development stage. Our clients want us to consult very early in the process and this gives us a major competitive advantage, both in terms of securing their trust and business, as well as ensuring we’ll match their product exceptions and needs. We’ve actually converted many of our clients from hot foil stamping to the many benefits of cold foiling, and we attribute this to the brilliance and luster generated from Eagle systems. It’s definitely a win-win for our customers and McLean. So much so that we’re now running cold foil every shift, three out of every five days.”

Whether you are looking to enhance your packaging offering or are a commercial printer that is looking to add embellishment to their print offerings, Eagle can help. Read up on our 2-Step Process on our blog and the Eagle Cold Foil Certification (ECFC) course. As you discover the power and support of the Eagle Systems methodology, we believe you will want to explore how to get one in your shop. Contact us to learn more. We look forward to helping you open doors to more opportunity and profit.