Eagles Systems are installed around the world, but there are many conversations we have with prospective clients that start with one question…

Why should we look at Cold Foil?

Printers out there, especially those that have a plethora of experience or where trained in the art of offset printing, know that the foiling process is generally a bit of a pain. In most cases, printers would have experience in the past with the hot foil process. We would define hot foil as:

The application of metallic or pigmented foil on to a solid surface by application of a heated die onto foil, making it permanently adhere to the surface below leaving the design of the die.

As a secondary process, the challenge with Hot Foil is that it doesn’t allow for easy applications in an inline printing process. Hot Foil also has a challenge with more detailed designs and the ability to transfer fine lines of foil for those delicate and stand out print compositions. While Hot Foil is still something Eagle Systems can help clients with, we find many people are looking for that next generation solution; one that is easy to apply, most cost effective and creates designs that once seemed impossible. This is where Cold Foil continue to shape the printing industry for commercial and packaging applications.

There are really three main reasons for why any offset printer should be looking at cold foil—and select Eagle Systems to help them.

Easy Inline, Two-Step Process

This short animation really explains the power of it all. We also have an Easy Two-Step blog you can read at your leisure.

Flexibility of Design and Media

By utilizing cold foil technology, printers are able to achieve designs that are just not possible using a hot foiling process. Moreover, the media that can be used is greatly widened and includes uncoated stocks. Learn more about the possibilities and impact in our Engineered for Your Success blog post.

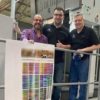

Industry Leading, Hands-On Training Course

From our perspective, if our clients are successful and making money in the print marketplace…we are doing our jobs at Eagle Systems as The Foil Experts. The best way to make this a reality in our humble opinion is to work hand-in-hand with our clients, which is why we offer the Eagle Cold Foil Certification (ECFC) course. It is a course that is administered at your location, with your equipment and team. The goal: allow you to leverage your investment to its fullest potential in the fastest manner possible.

For our team here at Eagle Systems, the answer to why is really a simple response; because you are in business to earn more business and stay relevant. Offset printing continues to provide that relevance especially in applications that are not achievable with digital print production. The depth of color, the richness of the final product and the ability to product cost effective runs are advantages we continue to deliver to our print buyers. Adding innovative Cold Foil takes your offset print offerings to another level, especially in the luxury print and packaged goods market.

We invite you to contact us today for more information on Eagle Systems, our process and the technology that is waiting to transform your printing business. Why just print, when you can print while adding a little bit of sparkle. We look forward to hearing from you soon…and be sure to follow Mike, Ellen and Eagle Systems on LinkedIn for insights into this exciting market.