During the early years of hot foil stamping, I was a young 15-year-old working with my father’s company building Brighten Leaf Pullers designed to attach to small automatic die cutting presses and clam shells. An extensive amount of pressure was applied to foil ribbons in those early days of hot foil stamping.

In the puller system, a supply roll was mounted on one side of the stamping press, and the foil was actually pulled through the press by mechanical rollers on the opposite side with uncontrollable pressure. Not only did the success of foil adhesion to the substrate lay heavily on the accuracy of the pull, if your supply was too tight – the foil would be damaged when adhered to the carrier.

Combine those production concerns with the slow speeds and one-size pull cycle, I knew that a large format foil solution was needed to improve the quality of stamped products. This led me to introduce the first electronic foil indexing machine in 1977.

Creating True Cost Savings with Hot Foil Indexing

The BOA System utilized DC motors and vacuum clutches to drive an index roller. This new technology helped create actual foil savings with a resolution in indexing of +/- .125”, and Eagle Systems’ Hot Foil Indexer has helped us take that even further down to +/- .002”.

The hot foil indexer opened the door to a step and repeat combination of any size. For example – the BOA would allow you to run 2” pulls 10 times, followed by a 20” pull to clear the roll. While this step and repeat combination does create tremendous cost savings in terms of foil, speed limitations were, and still are, a cause for concern due to substrate bonding, the heat transfer process, and the mechanical registration process.

This new technology process includes wrapping the foil around the head of the press in the opposite direction of the paper before being slightly pulled by a light nip on a continuous running roller known as a “take up roller” or TK. This light nip enables you to make the move in a 0.7 second window at a press speed of 3600 sheets per hour (sph). Eagle has been able to double their press speed to 7200 sph to achieve the same move in 0.35 seconds.

Mechanically, the move has been tested at speeds of 10,000 SPH and can easily be achieved. However the complex process of hot foil stamping, just doesn’t allow the transfer time or dwell time for hot foil to work. When it comes to hot foil stamping, the process is an intermittent cycle consisting of two phases that stop the sheet and foil for stamping, then the press opens up so the foil and sheet may advance for the next impression.

Blanket Gap Savings with Cold Foil

We introduced our Eco-Eagle Cold Foil System as an in-line foiling solution for offset presses in 2007, but before we introduced our foiler, we tested cold foil indexing in our factory. After seeing the results immediately, I knew this was not a direction Eagle wanted to go. We didn’t have the luxury of the intermittent cycles we saw in hot foil stamping.

Cold foil systems have to run continuously with the offset press it’s mounted to, and in order to make the move, or stop the foil for impression, the timing has to be perfectly synchronous because the window is extremely small.

For example, instead of a 0.7 second window at a press speed 3600sph – you have a 0.3 second window with cold foil. (0.15 seconds at 7200sph, 0.075 seconds at 10,800sph, etc.) In today’s production world, cold foil systems run along at press speeds around 11,000sph – and can easily run at speeds that are even higher.

This small window, unfortunately, does not allow you to stop the foil without stretching the carrier. This leads to a disturbance in the bound foil particles, much like the way ink on shrink wrap becomes transparent when stretched. This damaging effect will only allow the possibility of saving foil on gap at a very slow speed.

While mechanically, the foil carrier can be moved at these slower speeds, the quality of your results will be substantially inferior. The pin holing created from stretching the carrier leads to lead edge piling and swirling on press.

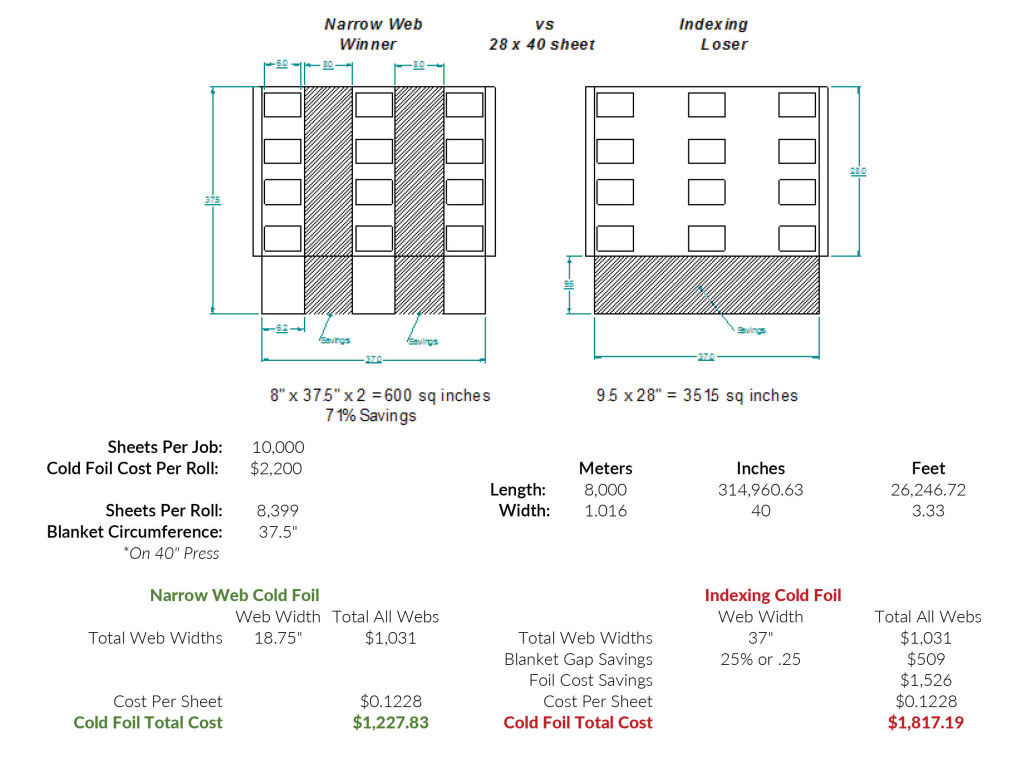

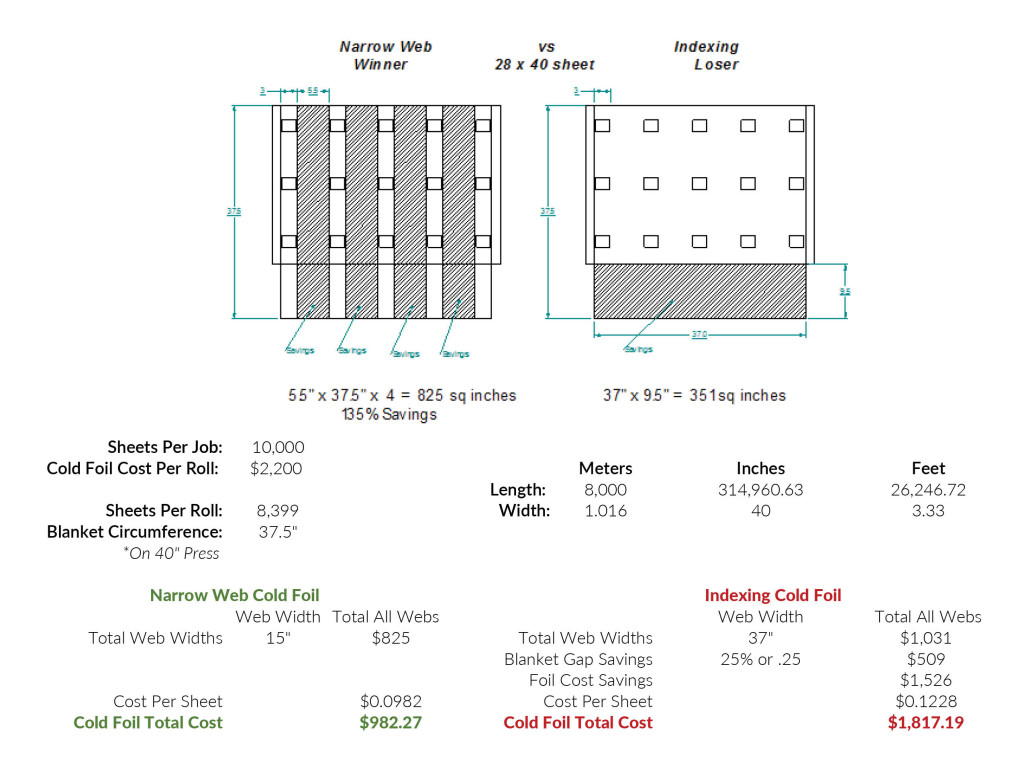

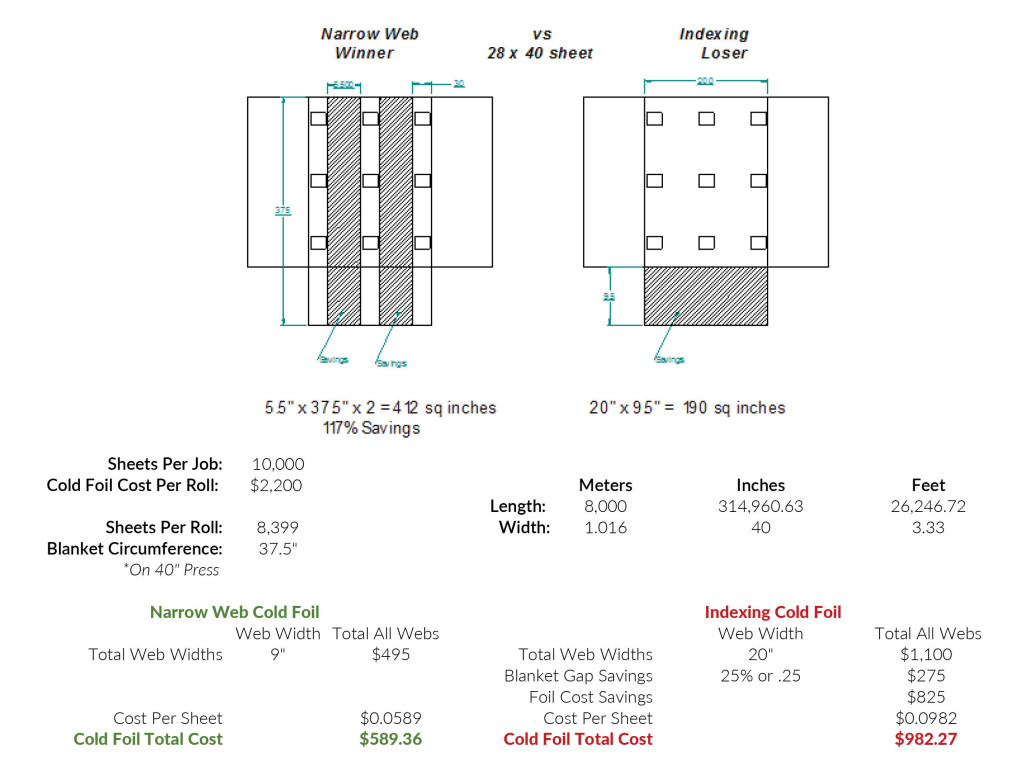

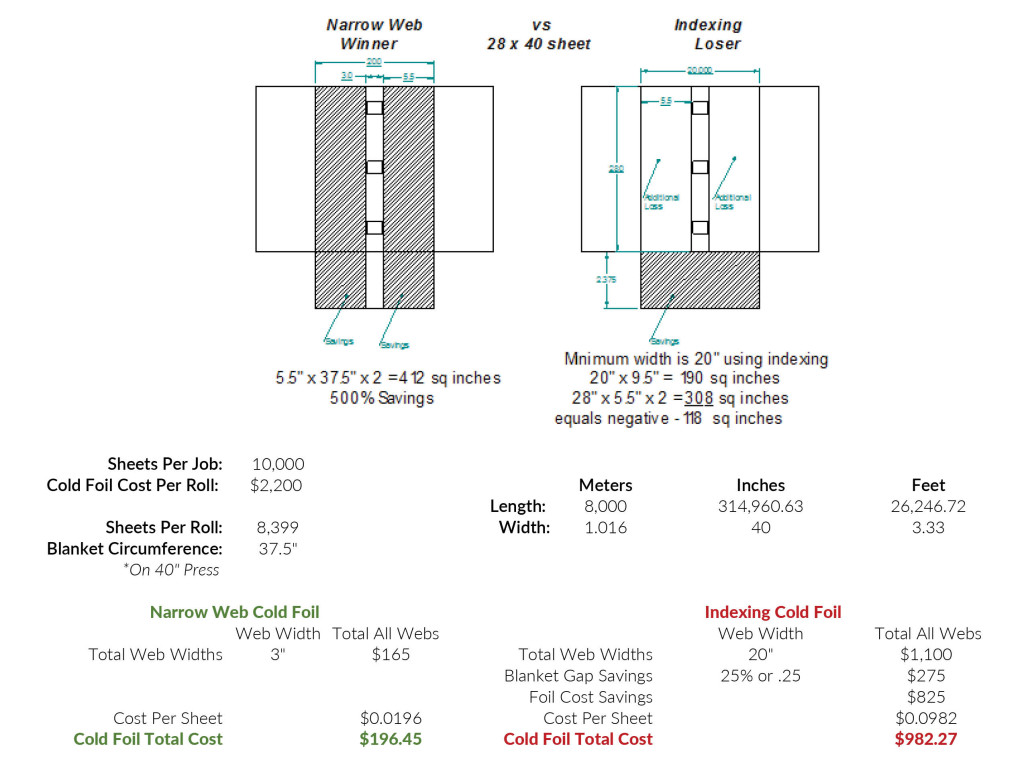

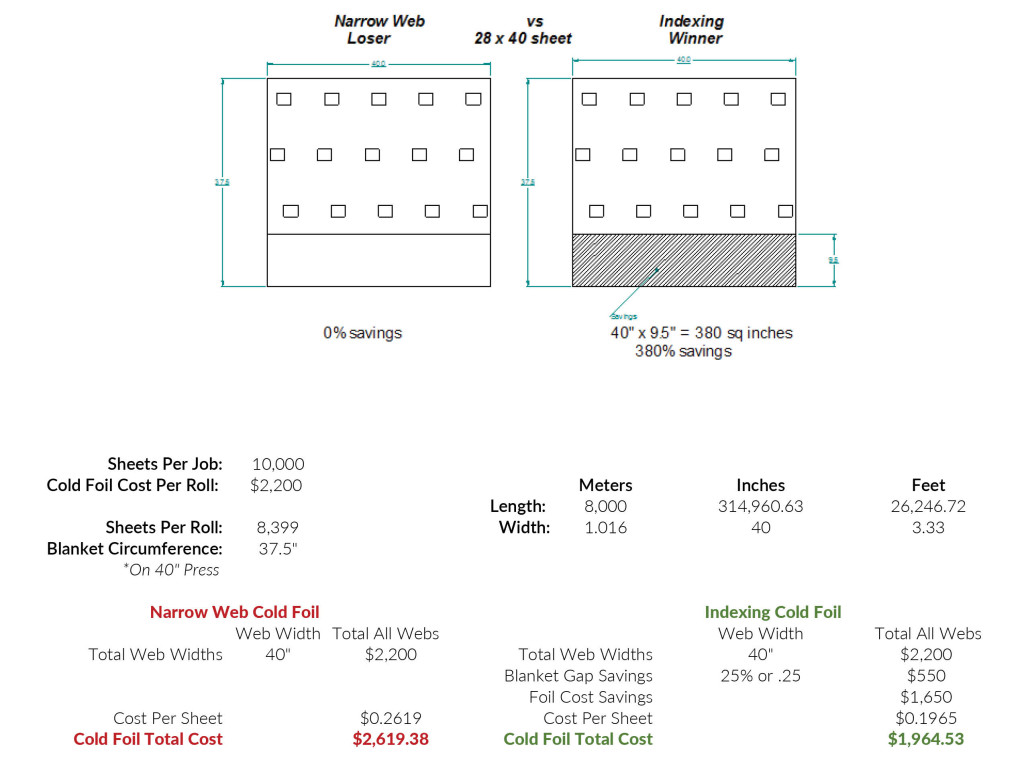

Yet the True Cost Savings Lies in Narrow Web

Looking at all the variables, narrow web can help you create substantial cost savings in most cases over indexing. While you can, of course, create savings in foil during indexing in some scenarios – the real world of packaging with narrow and multiple webs presents the largest cost savings overall.

First, indexing brings damage to the foil, and with the higher tensions – your ability to use high line screens is limited. By leveraging the proper equipment with Narrow Web, you’re able to run the roll continuously without damaging the foil. In fact, the stopping and starting of the foil’s movement at such a high rate actually causes more foil breaks than when running on a continuous basis. Furthermore, by creating a simple foil path, Eagle Narrow Web systems never touch the foil until it’s used.

Secondly, The dancer style systems used in cold foil indexing today battle an ongoing battle throughout the course of the run…they create foil dust. In all reality, foil dust is created from small particles of foil that are actually missing from your carrier. This is a defect to your product, and in some cases – specially formulated foils are required for improvements. These additional costs need to be considered.

Additionally, these dancer systems don’t allow for offset foil running – opening the door to even more loss. For example, with Eagle Systems’ cold foil – you can run one single web anywhere on the width of the sheet. The dancer systems require a sort of balancing act, and lead to a lot of foil waste.

If you need one 4” web in the middle of the sheet, you would also need 2 additional webs (combining for a 12” span) to balance out the dancer system from counter leaver problems. That’s 8” of foil you’d be forced to throw away.

Finally, a major problem to be considered is the cost of ownership of an indexing machine. With the foil dust present, all of these systems require constant repair of “wear items” that are not included in the warranty, and cause tremendous down times. To top that off, in a few years when they’re no longer repairable – the cost to replace your system can be extremely expensive. These costs need to be figured in on top of the initial purchase.

So Let’s Compare Side by Side

To round out our post, I wanted to share with you what a side by side comparison of costs for various projects on both the narrow web and the indexer. Please don’t hesitate to contact us if have any questions.