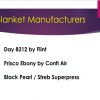

Most folks think they know their settings and just shoot for the same number all the time. This is usually true but they usually have optimized their settings and have built faith in the their numbers. When setting up your adhesive for the first time on a new substrate properly find your working window of opportunity. Skew the adhesive on the sheet in density settings example: on the left .35 to the right side, up to .65. Turn on foil and look for pin holing on .35 side and tailing or mud cracking on .65 side or anywhere in between. If neither happening, that is great, open the window more. Once you find your low number and your high number, set the entire sheet to a little above ½ in that mid-range. Now your good to go, and with a large window, you should not have to worry about adhesive settings all day. Cold Foil is mathematical and by the numbers, save the paper brand and thickness and document your findings. It takes a little time to build your book of these settings, and all should be confirmed periodically or if trouble should happen, come back to the basics. Numbers are dependent on substrate manufacturer, substrate thickness and blankets used on foil tower.