At Eagle Systems, we are on a mission to add sparkle to offset print all across the world. We believe that all print shops should have the opportunity to add…

At Eagle Systems, we are on a mission to add sparkle to offset print all across the world. We believe that all print shops should have the opportunity to add…

As a print shop owner or operations manager, we don’t have to tell you the hassle adding foil can create. Traditionally, it has required highly-specialized machines that were difficult to…

If you have been following our social media sites over the past six months, you probably are well aware of the Eagle Cold Foil Certification Course (ECFCC) that we offer to all of our customers. The course is designed to ensure that all Eagle customers perform at the highest standards available to cold foil technology.

The course is a comprehensive eight-hour program that is engaged at the print facility. As a result, we are able to adequately teach in their environment. This is helpful because each print shop has it’s own set of complications and we are able to deal with each scenario organically. Our overall goal is to improve knowledge, techniques, as well as increase the knowledge and understanding of Eagle Systems for press operators and upper management. This will ensure a great ROI for our customers.

Here’s what our customers are saying about the Eagle Cold Foil Certification Course (ECFCC).

The packaging market is growing by the minute and it’s not slowing down. You may have heard talk following drupa this past May and more recently GRAPH EXPO about the so-called “packaging revolution” and how it is opening the door to new revenue streams for printers.

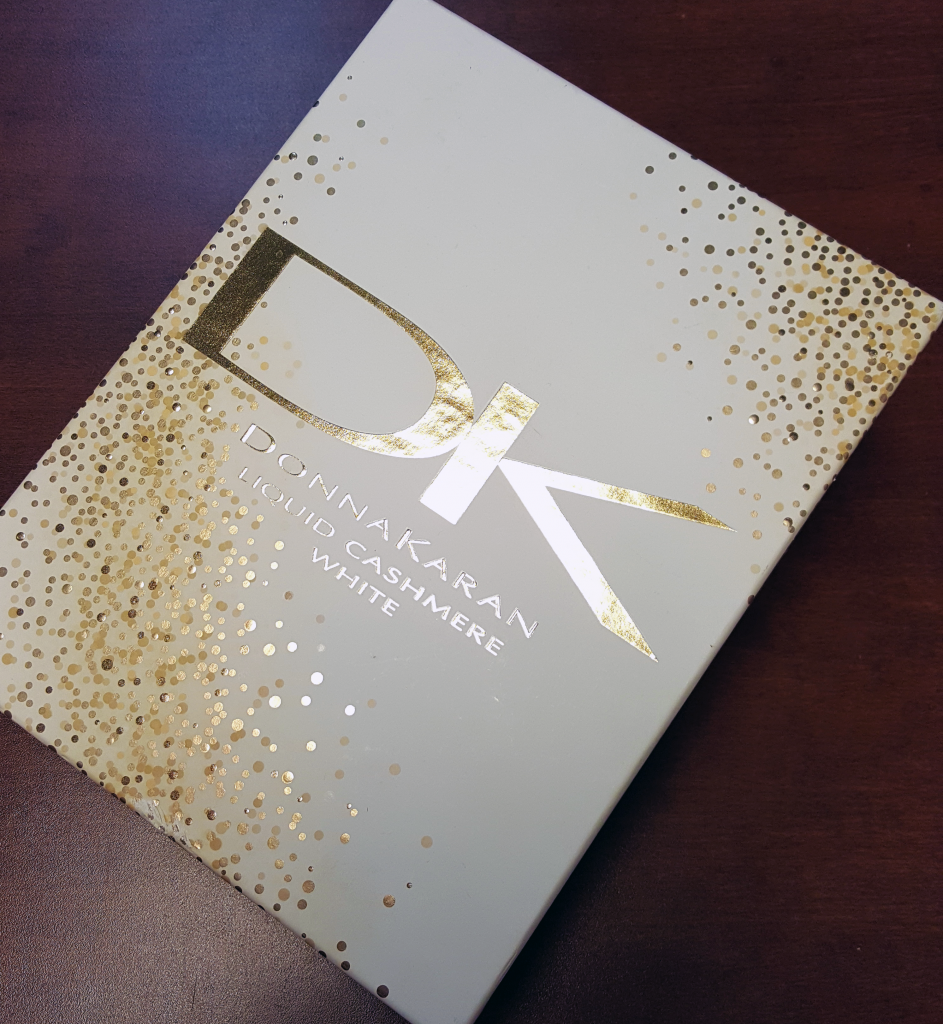

According to a recent article published in Strategies, “the first point of contact with any product is almost always the packaging” (read more). In the digital age, packaging has entered a new set of demands. Consumers crave a personal experience. Packaging must extend beyond the physical realm of brand representation and make a mark on the psyche of the consumer. The result moves beyond shelf appeal and enters into the arena of brand loyalty and sales as a result of the consumers’ feelings of valued experience.

The Eco-Flow Cold Foil System is an extension that works in conjunction with most presses. In fact, the extension can be customized to just about any size press all the way up to 145” (take a peek at our installation gallery). We have been working on designing a 162” machine for Wide Format printing giving printers more options for their customers.

A question that many of our prospects and future customers ask is, how difficult is it to install the technology and how will it affect overall workflow in the print shop? After all is said and done, in what way will Eagle technology help bring in a return?

Our president Michael B. King said in an interview with NPES last year: “I truly believe history repeats itself and, as we emerge from a recent bad economy, companies look…

We’re just a few weeks away from the big drupa trade fair in Düsseldorf May 31-June 10, and we can’t help but be excited about the major emphasis on packaging…

During the early years of hot foil stamping, I was a young 15-year-old working with my father’s company building Brighten Leaf Pullers designed to attach to small automatic die cutting…

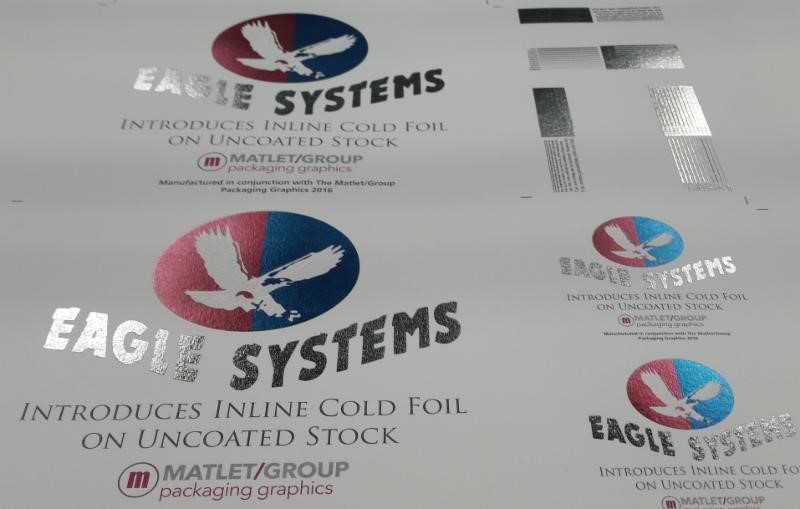

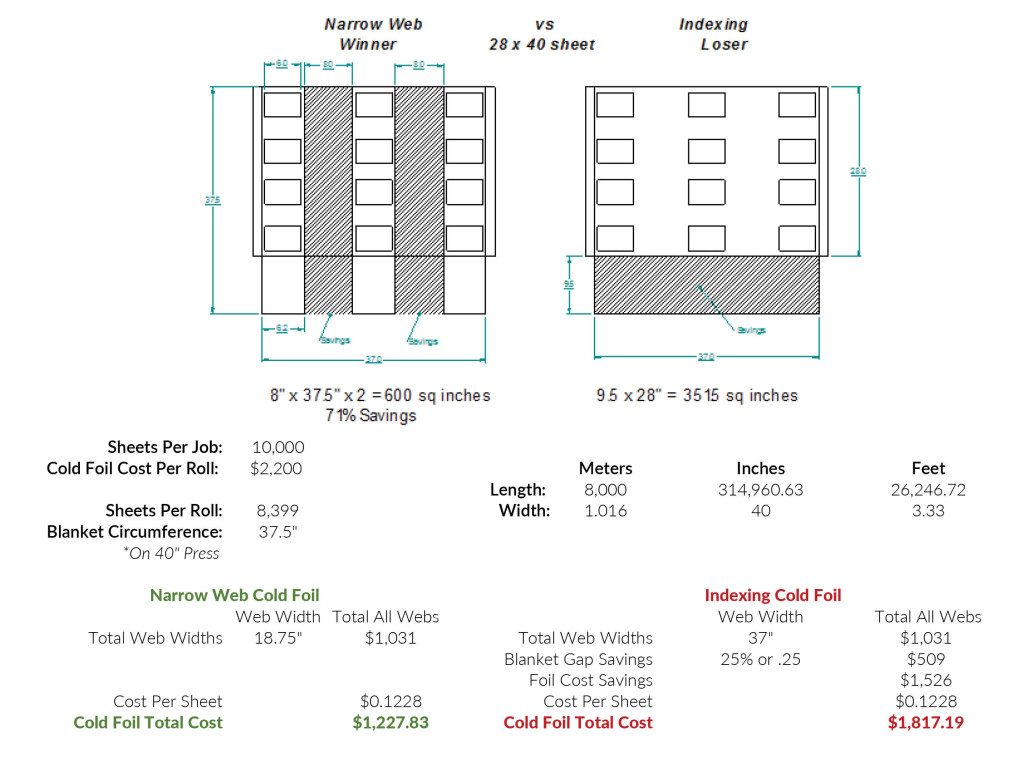

In the sheet-fed production world, there are many ways to add a touch of foil to your packaging and commercial print jobs. One of the most notable ways to apply…