Have you ever gotten trapped by the whirlwind of your day-to-day job? It happens to all of us, especially in a fast-paced and competitive marketplace like printing. But what is the opportunity cost? It might surprise you how much it is affecting your print production.

At Eagle Systems, we strive to help clients implement and optimize the use of cold foil to differentiate their offset printing offering to their customers. We find that even after we sell a customer an easy-to-use Eagle System, that there are still improvements and education that can really pay off. In fact, we started the year off with a blog challenging all of our customers to take the Eagle Cold Foil Certification (ECFC) course.

The reason? We still believe what we wrote then:

“It is simple, this course is designed to take the investments you have made in our Eagle Cold Foil solutions and refine not only the system for the best output, but engage and educate your Executives and operators to provide superior understand, process and promotion of cold foil.”

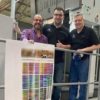

Don’t worry if you haven’t taken us up on the ECFC course yet, there is still plenty of time! One of our customers in Dallas, Texas—Cartamundi—just completed their certification. You can read their full story in a recent article from Printing Impressions, but we wanted to share why they saw value in investing in cold foil education.

First, they had the Eagle Cold Foil System installed in 2013, so it had been a moment since they had taken an opportunity to get all their press operators on the same page. Moreover, they had also extended their operating hours and added team members.

Second, the team at Cartamundi found that there were differences in understanding on how the Eagle System worked and how it affects the materials running through the press. Since Cartamundi had seen a competitive advantage from adding cold foil from Eagle Systems to their production capabilities, the management team wanted to retain that by getting everyone certified, as well as, making sure their production process was optimized.

“We wanted every pressman to understand how cold foil on press applications impacts our stock,” said Dave Adams, Press Superintendent. “There was a lot of misconception, and we were able to demonstrate how the cylinder pressures play a role in the process.”

The investment to participate wasn’t small for Cartamundi either; they committed to shutting down their entire press operations for one and half shifts during a Saturday to make certain that every one of their 20 pressmen and eight management and support staff could attend and absorb the ECFC information. The payoff, however, was a better, more consistent application of cold foil and a continued ability to standout with a little bit of sparkled as compared to their competition.

So how do you get started with Cold Foil or take us up on enrolling in the Eagle Cold Foil Certification (ECFC) course? First, take a look back at our 2017 ECFC Challenge where we share experience from past ECFC graduates. Then contact The Foil Experts to learn more about the course or the Eagle Cold Foil solutions. We look forward to hearing from you!