Printers in today’s marketplace have to continually look for a competitive edge. Cost savings can only take a print shop so far, but a new market can create growth with lasting benefits. The challenge does come back to cost—how do you cost effectively break into a new market? At Eagle Systems, we help our clients break down the barriers to new markets, especially in the packaging or carton converting market space. We do this by providing a superior solution to traditional cold foil production, thereby giving our clients access to future growth.

Printers in today’s marketplace have to continually look for a competitive edge. Cost savings can only take a print shop so far, but a new market can create growth with lasting benefits. The challenge does come back to cost—how do you cost effectively break into a new market? At Eagle Systems, we help our clients break down the barriers to new markets, especially in the packaging or carton converting market space. We do this by providing a superior solution to traditional cold foil production, thereby giving our clients access to future growth.

It is natural to be curious as to how we help clients access new markets and achieve success. With Eagle Systems, The Foil Experts, we provide what we like to call a “fool proof” process for adding inline cold foil to most offset presses. You can read more about that in our recent 2-Step Fool Proof Process blog; it truly changes how one looks at printing and the addition of cold foil.

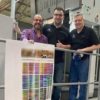

In fact, one of our clients in Canada was able to make a move from being mainly a commercial printer to competing in the carton converting, or in layman terms packaging, marketplace. Glenmore Custom Print + Packaging, has seen a big change in their business since they installed their Eagle Systems Cold Foil unit and it all happened by chance with a demonstration at one of the world’s largest trade shows a few years back now.

A couple of DRUPA trade shows ago (they happen every four years), James Rowley, General Manager at Glenmore, happened on the Eagle Systems stand. What he saw there he knew was different, though he wasn’t sure it was the right fit for Glenmore. However, the difference stood out and that stand out sentiment resonated with people both in operations and sales back at Glenmore. Rowley knew niche markets were driving growth in the print industry and they had their eye on a different look they could offer to the carton converting market. A notion that has transformed the company from primarily being a commercial printer to being closer to a 50/50 provider of commercial print and packaging.

The Eagle gave Glenmore a competitive edge by allowing them to offer something different, high-end and, from a production perspective, easy for their customers. “Our folding carton side of the business has grown as a result of having this equipment,” says Rowley in an interview with Folding Carton Industry Magazine. A result we here at Eagle Systems strive for and know all our clients can achieve. Rowley went on to say, “We have to stand out in a different way and provide a product that our competitors can’t produce. We’ve gotten a few nice pharmaceutical jobs because of it. It has definitely fueled growth for us.”

Another interesting part of the Glenmore story is the success of the installation, one of the first of its types for Eagle Systems. As we say at trade shows and in our brochures, you can install an Eagle Systems Cold Foil solution on almost any offset press. Glenmore put that to the test with the first install of the easy-to-use and fully automatic system on a Heidelberg XL press. The XL is an impressive UV offset press with 106 eight-color plus coater. Adding the twin-tower cold foil Eagle to that has resulted in a game changer for Glenmore.

Opening the door to a new market, in the same way Glenmore has done, might not be as difficult as you think. Let our experts at Eagle Systems, The Foil Experts, help remove the barriers and compete with much larger business…and win!

The key is the fool proof process and easy ability to change from normal four-color printing to cold foil embellishment. Contact us today to find out more and start down your path to winning in a new market.