In May of 2016, we at Eagle Systems launched what we believe to be one of the most important value-adds for our clients: Eagle Cold Foil Certification Course (ECFC). Why is this course so important and why should it be on the lists of resolutions you keep in 2017? It is simple, this course is designed to take the investments you have made in our Eagle Cold Foil solutions and refine not only the system for the best output, but engage and educate your Executives and operators to provide superior understand, process and promotion of cold foil.

In May of 2016, we at Eagle Systems launched what we believe to be one of the most important value-adds for our clients: Eagle Cold Foil Certification Course (ECFC). Why is this course so important and why should it be on the lists of resolutions you keep in 2017? It is simple, this course is designed to take the investments you have made in our Eagle Cold Foil solutions and refine not only the system for the best output, but engage and educate your Executives and operators to provide superior understand, process and promotion of cold foil.

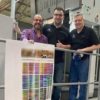

ECFC is a comprehensive and hands-on eight-hour program that is conducted on-site at our user’s production facility. The course is designed to provide additional education of the cold foil process, techniques that will improve operator processes and key elements to Executives to drive higher quality and Return-On-Investment (ROI).

Structured with two hours of classroom and six hours of direct on-press interaction, the course offers not only education from our Eagle experts, but unique test forms that are designed for failure and will be run off each applicant’s system to ensure fine-tuning and compensation for real-world factors. The benefits of certification include the removal of common process obstacles such as pin-holing and mud-cracking, superior processes for improved productivity, increased ability to promote cold foil, drive ROI and maximized performance of the Eagle Cold Foil system.

What kind of results could you see from your company becoming Eagle Cold Foil Certified?

First, you will see an improvement in every aspect of your daily processes. Our first graduate of the Certification course, Packaging Graphics of Matlet Group, had this to say:

“The Eagle Cold Foil System has been a very successful investment for Packaging Graphics,” said John Gaffney, Packaging Graphics President. “The Eagle system’s performance was consistently strong, and yet the certification training and education was able to fine-tune every element of the process. It simply made a good thing even better.”

Second, improve the speed of your make-ready and throughput while potentially reducing material usage. A more recent graduate of ECFC, D’Andrea Graphic Communications (dgc), shared these specific business improvements after completing ECFC:

“First of all, make-ready is substantially faster and overall product quality is noticeably enhanced. Second, throughput has been accelerated by between 10% and 15% on cold foil projects. And third, we’re experiencing about a 15% to 20% reduction in material use. This element alone has translated to $1000 to $2500 in additional profits, depending upon the job. The programs paid for itself in the first week.”

Finally, invest in your people and dial them into coil foil as much as you dial-in your system to produce the highest quality output. With advanced knowledge shared by our experts you can change how your team approaches their work. Glenmore Custom Print + Packaging had this to say about their experience:

The press staffers now have an in-depth working knowledge and understanding of the cold foil process. Not just the what’s, as in what to do, but the why’s and how’s. Our people are now as dialed in as our system is. We are reaping the rewards every single shift with faster make-readies and noticeable quality jumps. The class, as promised by Mike, was well worth the investment in time and resources,” said Stefan Congram, Operations Manager.

The above only scratches the surface of how we believe the Eagle Cold Foil Certification Course (ECFC) will benefit your company, team and customers in 2017. We invite you to get in touch with us to learn more about ECFC and schedule your one-day course to ensure you maximize your ROI and reach your goals even fast this year. We look forward to hearing from you.