Michael B. King

President & CEO

Eagle Systems, Inc.

President & CEO

Eagle Systems, Inc.

As the designer / inventor of all Eagle System Foil Machines, I started at the early age of 15 years old, working for my father’s company building a hot foil puller called Brighten Leaf Pullers which were attached to small automatic die cutting presses and clam shells.

Within a couple of years I realized there was a need for a large format foil solution so I created the first electronic foil indexer called the BOA System in 1977. This new technology was most effective in creating actual foil savings with a resolution in indexing of +/- 1/8 of an inch.In 1990 I created the Eagle Systems Hot Foil indexer with high resolution +/- .002 thousandths of an inch creating the most extreme results in foil savings.

In 2007 I started developing and created the Eco-Eagle Cold Foil System an in-line foiling solution for offset printing presses.

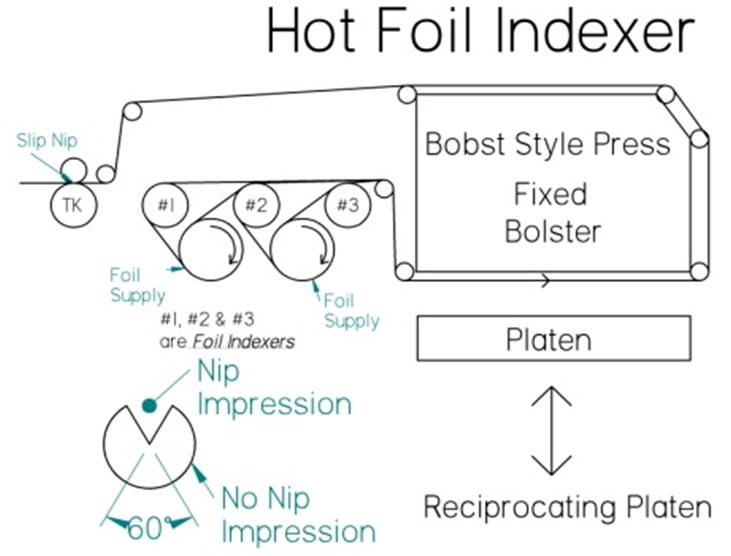

The first electronic foil indexing introduced in late 1977 by Mike King on a Bobst press , was made of dc motors and vacuum clutches driving an index roller. The foil would wrap around the head of the press in the opposite direction of the paper direction and then be slightly pulled by a light nip on a continuous running roller called a take up roller (TK). This system then and still today allows step and repeat of any combination of sizes.

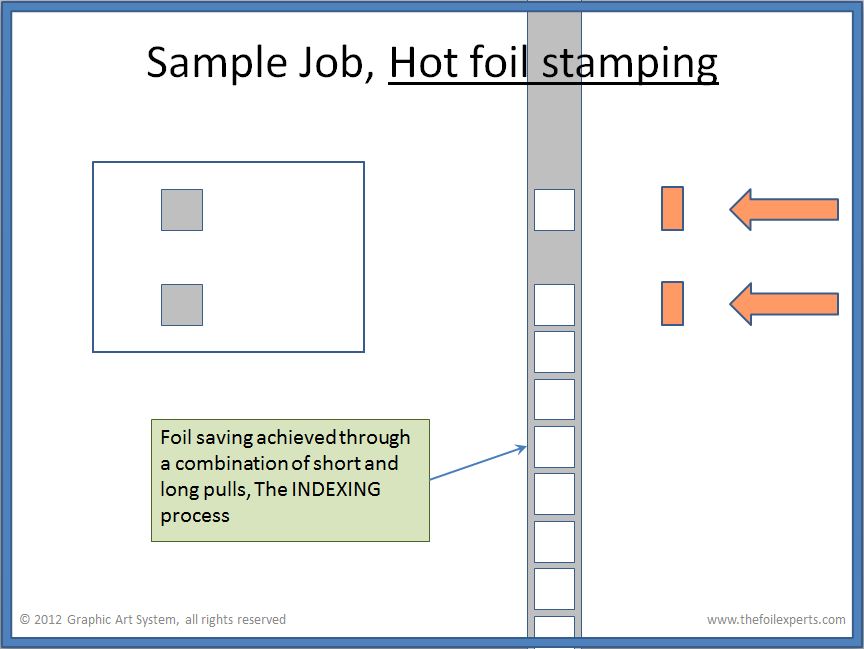

In the case of Hot foil stamping as illustrated, the process is INTERMITTENT and the process cycle includes two phases before it repeats:

Assuming the press runs at 5000sph

Click to see an animation of the Foil movement on Cold Foil

Assuming the press runs at 10,000sph